Task

Product design and product development in cooperation with chief researcher Hanne Maribo Ph.D and veterinarian Lotte Skade from Seges as well as Agrobiologist Ph.D. Rikke Thomsen from Center for frilandsdyr to develop an animal friendly fixture for the treatment of piglets in conventional, organnically and free-range farms.

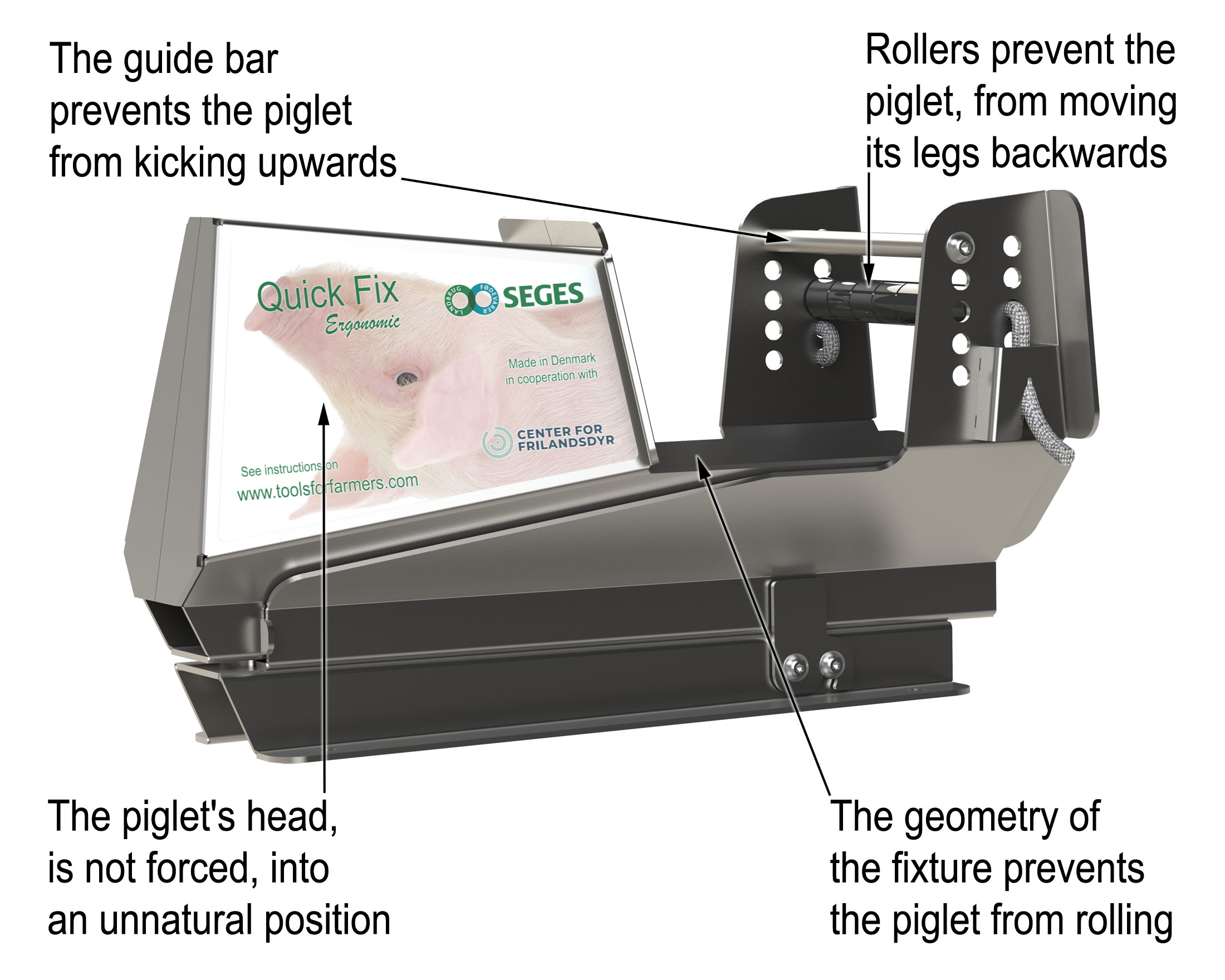

The fixture had to be able to hold the piglets as gently as possible, during anesthesia and other injections, as well as during castration of male pigs.

MY contribution

Product design and product development, research and interview of users, as well as development and construction of a number of prototypes and ongoing evaluation of their function together with Rikke Thomsen and Lotte Skade.

Design, construction, production of graphics, website, stickers and setup of user manual and prototype production as well as 0 series, of the final product.

Product design and product development.

Product design and product development in collaboration with chief researcher Hanne Maribo Ph.D and veterinarian Lotte Skade from Seges and Rikke Thomsen Agrobiologist Ph.D. from the Center for frilandsdyr.

We have developed this product to improve conditions for pigs and farmers, in connection with the new Danish rule on local anesthesia of the piglets before castration.

Why castrate male pigs ?

If the pig is not castrated, there is a risk that the meat will have a boar smell and a taste we do not like in Europe.

So the traditional Christmas with roast and duck would be a boring experience for many, and you can’t build a business on that.

Now the pigs must be anesthetized before the procedure.

According to current Danish rules, pigs must be castrated with the use of local anesthetic and pain relief during the pig’s 2nd – 7th day of life.

For generations, pigs have been castrated without anesthesia, with the well-known castration knife, a small black curved folding knife that the farmer had in his pocket. In recent times, scalpels and sharp castration forceps have been used and the process made more efficient.

But now the pigs must be anesthetized before the castration is carried out. They are injected into the testicles with anaesthetic, and 5 minutes must pass before the castration can be carried out, because that is the time it takes before you can be sure that the anaesthetic has its effect.

Traditionally, pigs are held between the Farmers legs.

Skilled farmers and Eastern European workers often hold the pig between their legs during the procedure, both during injections of various kinds and during the castration itself.

It happens from time to time that they cut themselves or stab themself in the thigh, with a course of illness as a result.

Gentle but effective.

Seges and Center for frilandsdyr wanted to make the process safer for the farmer and more animal-friendly.

The most used fixture on the Danish market squeezes the larger pigs and keeps their necks stretched out in an unnatural position, which does not make them scream less.

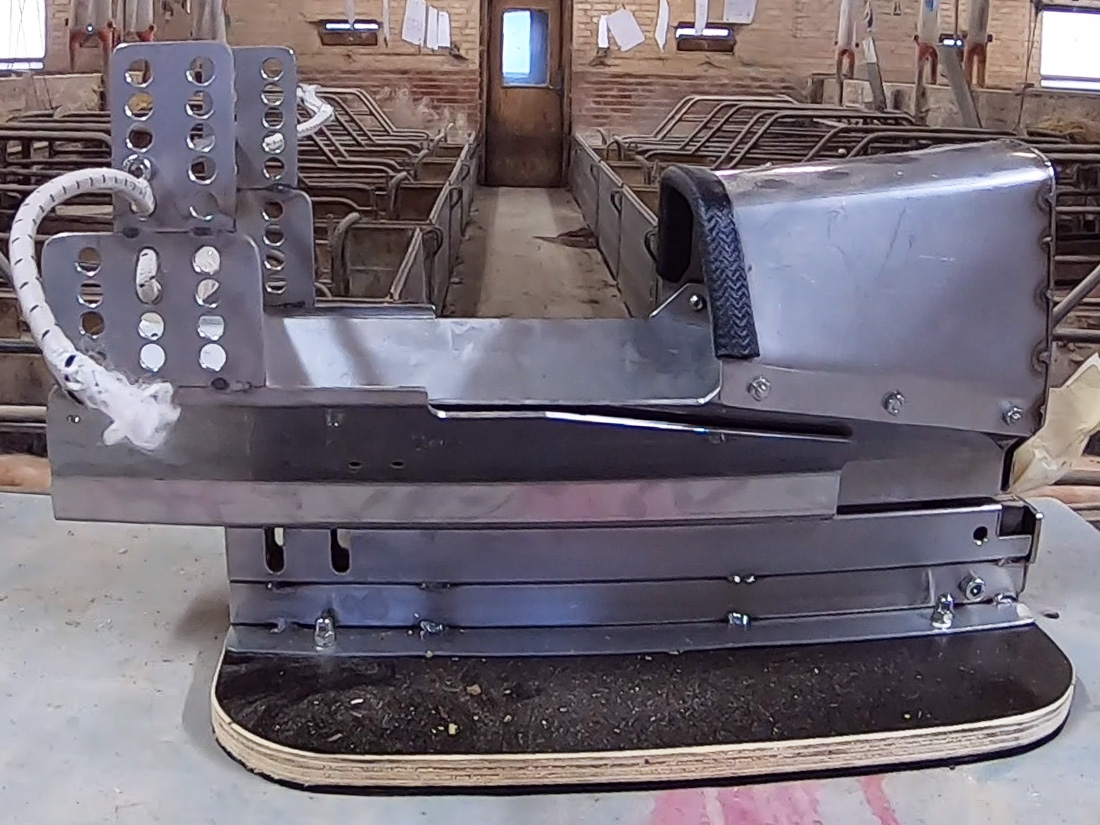

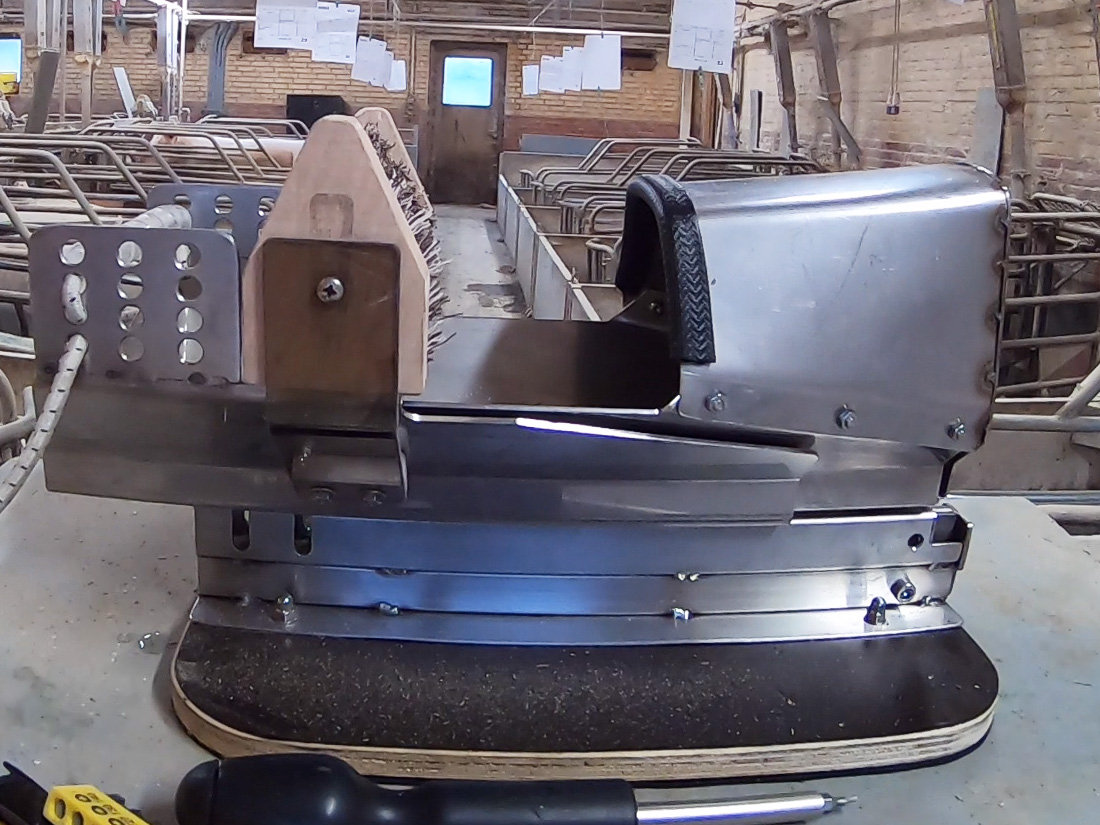

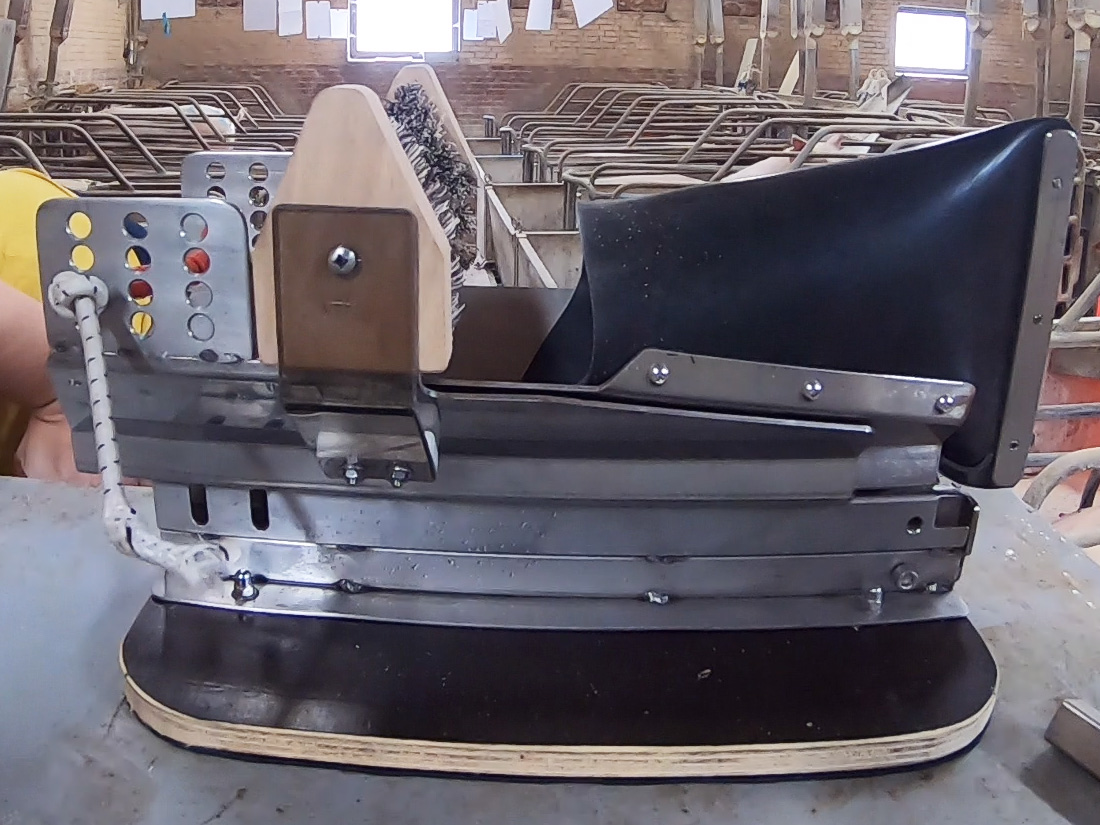

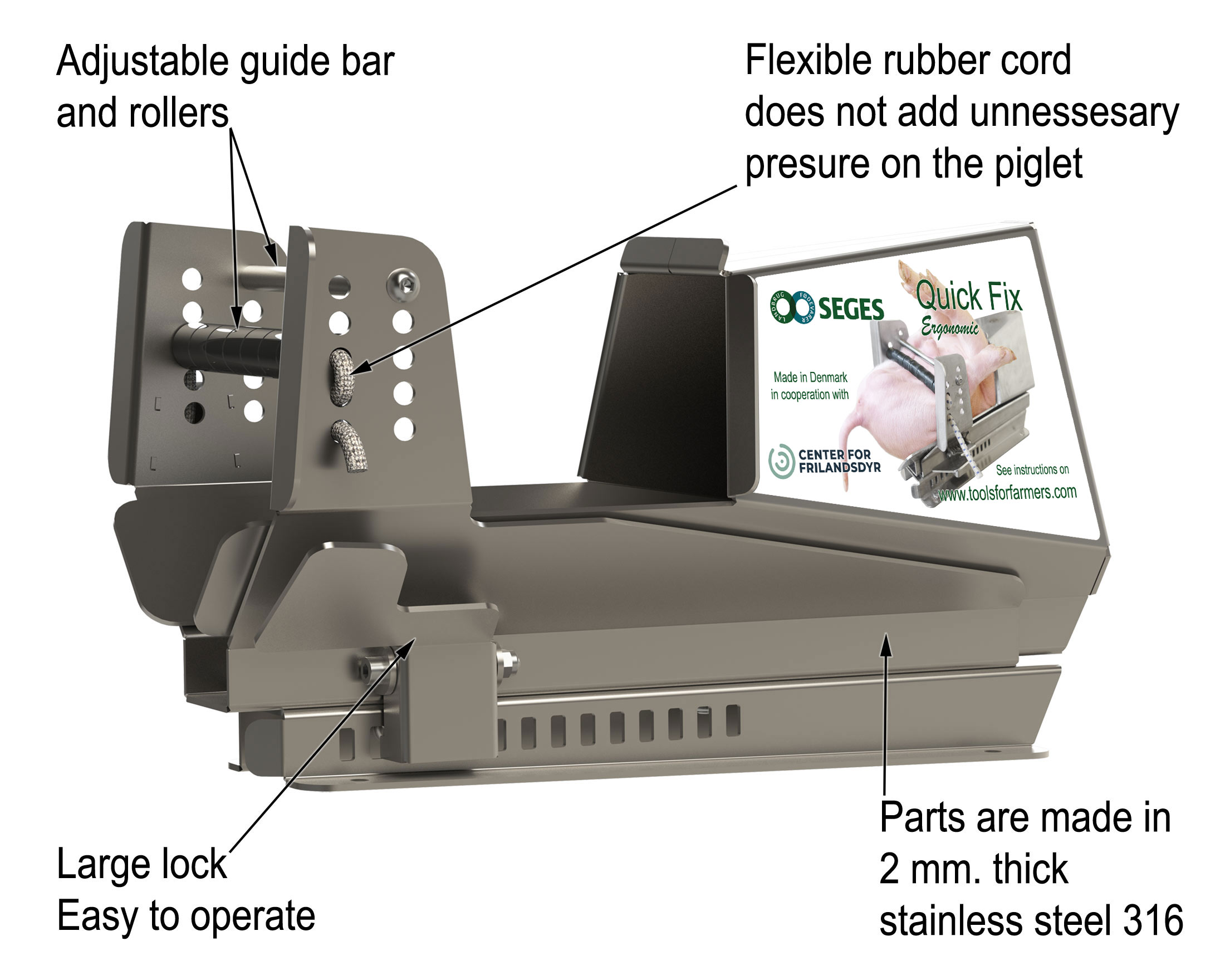

After many tests and prototypes, we have arrived at a fixture that the pig fits well in. It does not lie on the spine, but is supported on the body. and the fixture is suitable for both large and small pigs, up to 7 days old.

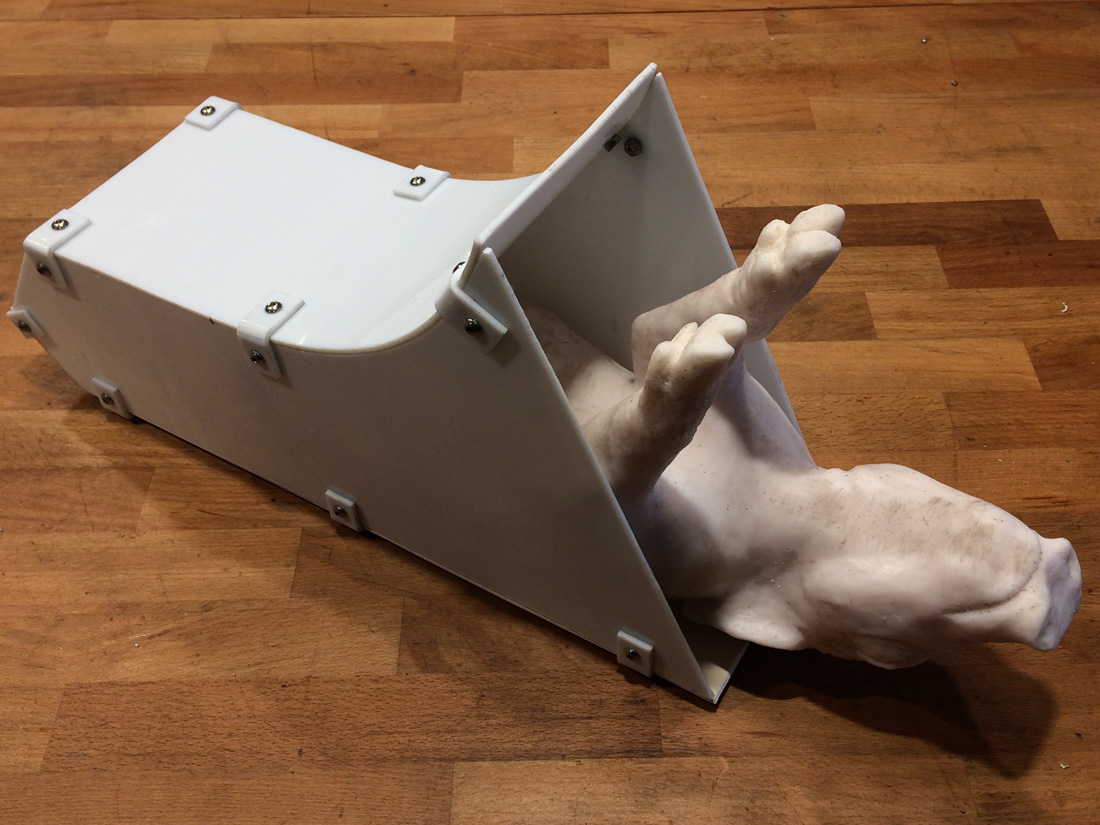

Early tests with a fixture that was made of rubber, where the pig lay as if between two pages of a book, showed us that when the pig is lying on its back it wants to bend its head upwards, it can do that in this product. We have tried to hold the pig as gently as possible, in an attempt to avoid provoking an umbilical hernia.

Another argument for using the fixture is that it is quick to operate, which is important when you have to get pigs out and in several times, because of the waiting time for the anesthetic to take effect.

The actual injection into the testicles must take place at a certain angle, this angle is also easier to get perfect when the pigs lie in the same way, every time.

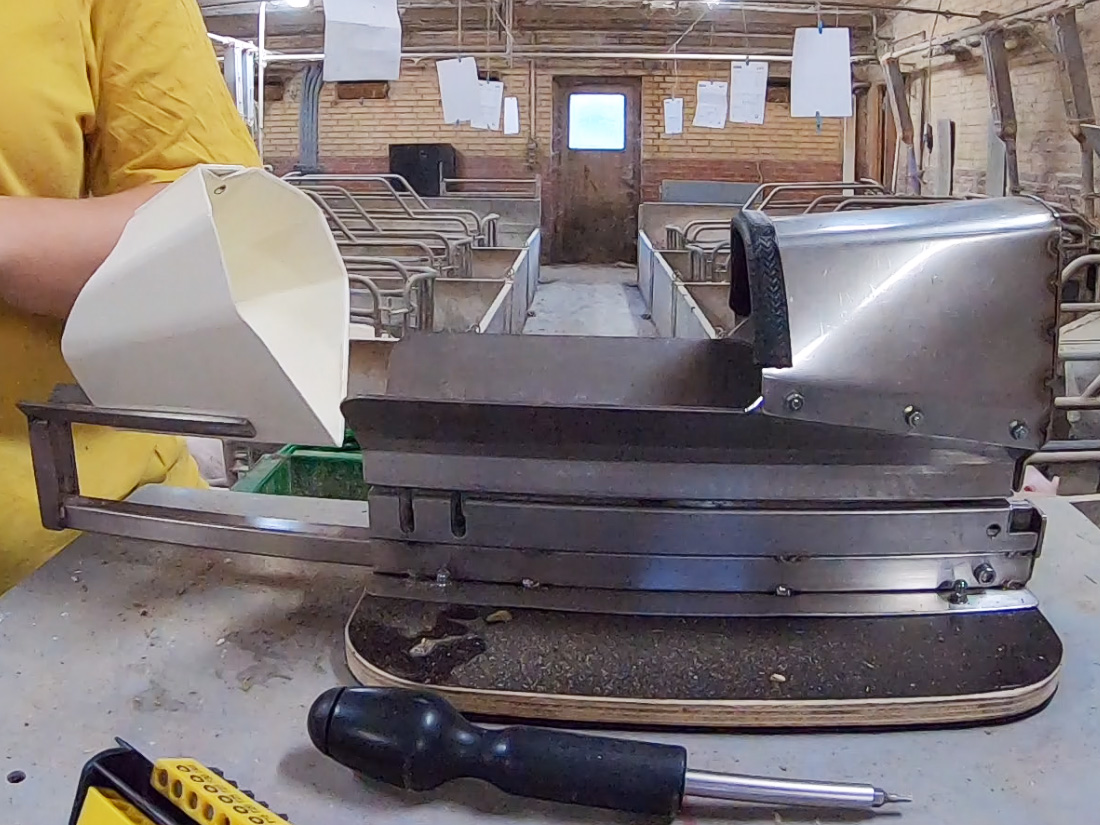

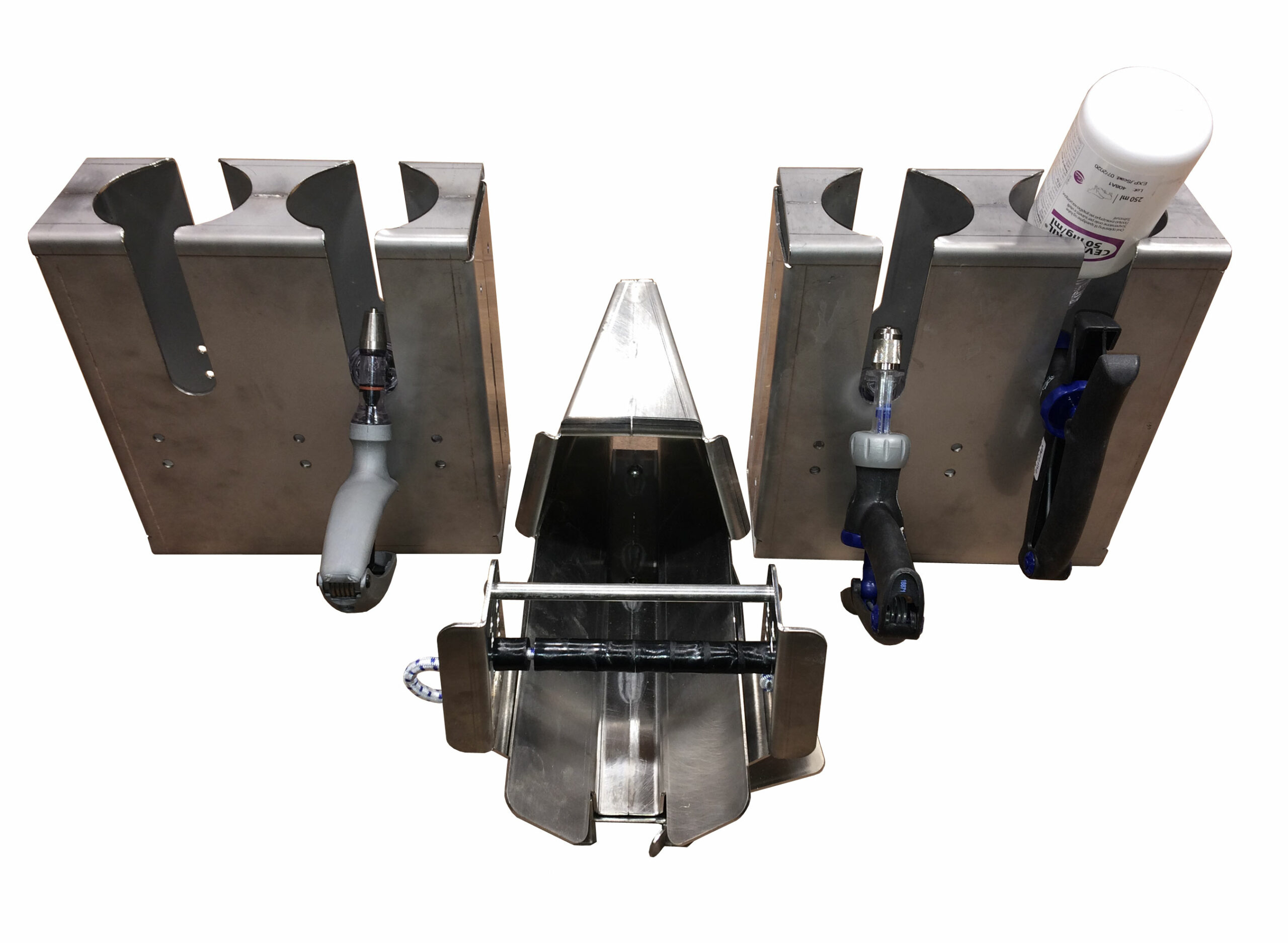

Easy to disassemble before cleaning.

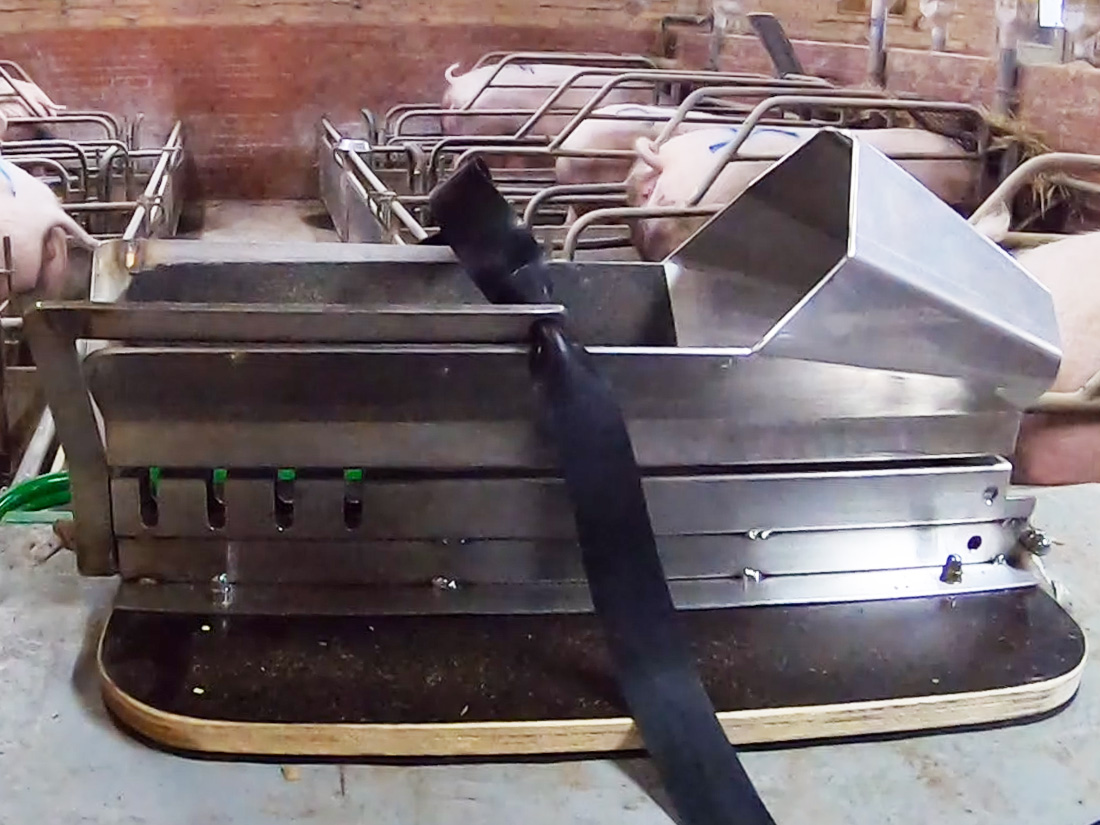

The daily cleaning of the product, which is often strapped to a cart or similar, is really important.

We have made it possible to separate it into 2 main parts with a single handle, so you can get into all the corners when cleaning.

Testing the product.

In tests, the elastic has lasted for approx. 10,000 treatments without being worn out.

It has been shown that it is easier to put the pigs in and take them out than with the traditional fixture that is most often used.

The pigs lie better and do not easily roll around when loading and unloading,

You can see it in the video below.

Ses how it works.

Instruktional video.

Stickers on the sides explain how to place the pig in the fixture and an instruction manual, in the package explains the entire procedure.

We have also produced an instructional video which you can see on the left.

Here you can see how easily the pig is put in and how little it rolls when it is taken out. We do not show the local anesthetic injection or castration in the video.

www.toolsforfarmers.com

Here you can see the website which has been made with instructional videos, user manual and which shows the suggested retail price and spare parts.

Links to dealers:

Prototypes for testing.

Where should you start and where should you stop when creating a new product that must be newer and better?

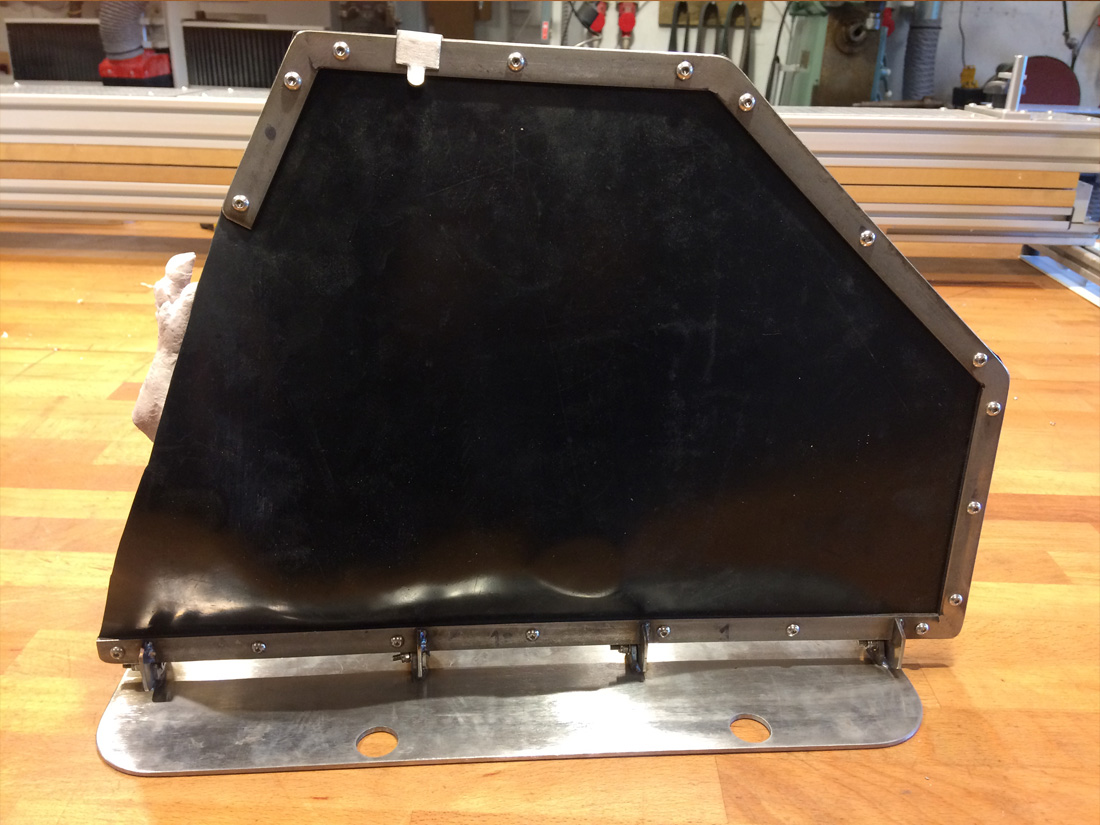

We started by analyzing what already exists, and based on that we created new ideas that were outlined and evaluated. Quick and dirty prototypes were made of the selected ideas to test what could be used and what could not be done.

We had rubber pigs from another project that we used for the initial ergonomic studies. What looked promising was later tested on live animals.

You can spend a lot of time on the wrong thing, so we figured out quite quickly in the process to make some kind of test rig. We could then mount different functions on it, and in different combinations test it. I don’t have a count of all the combinations veterinarian Lotte Skade and agrobiologist Ph.D Rikke Thomsen experimented with.

We ran 5 test rounds, where I made new ones for the prototypes after each test. When we thought we were on target, we made a number of prototypes that were tested by farmers and a 0 series of 10 to see how they were to produce.