Solvandrenser til tredje verdens lande.

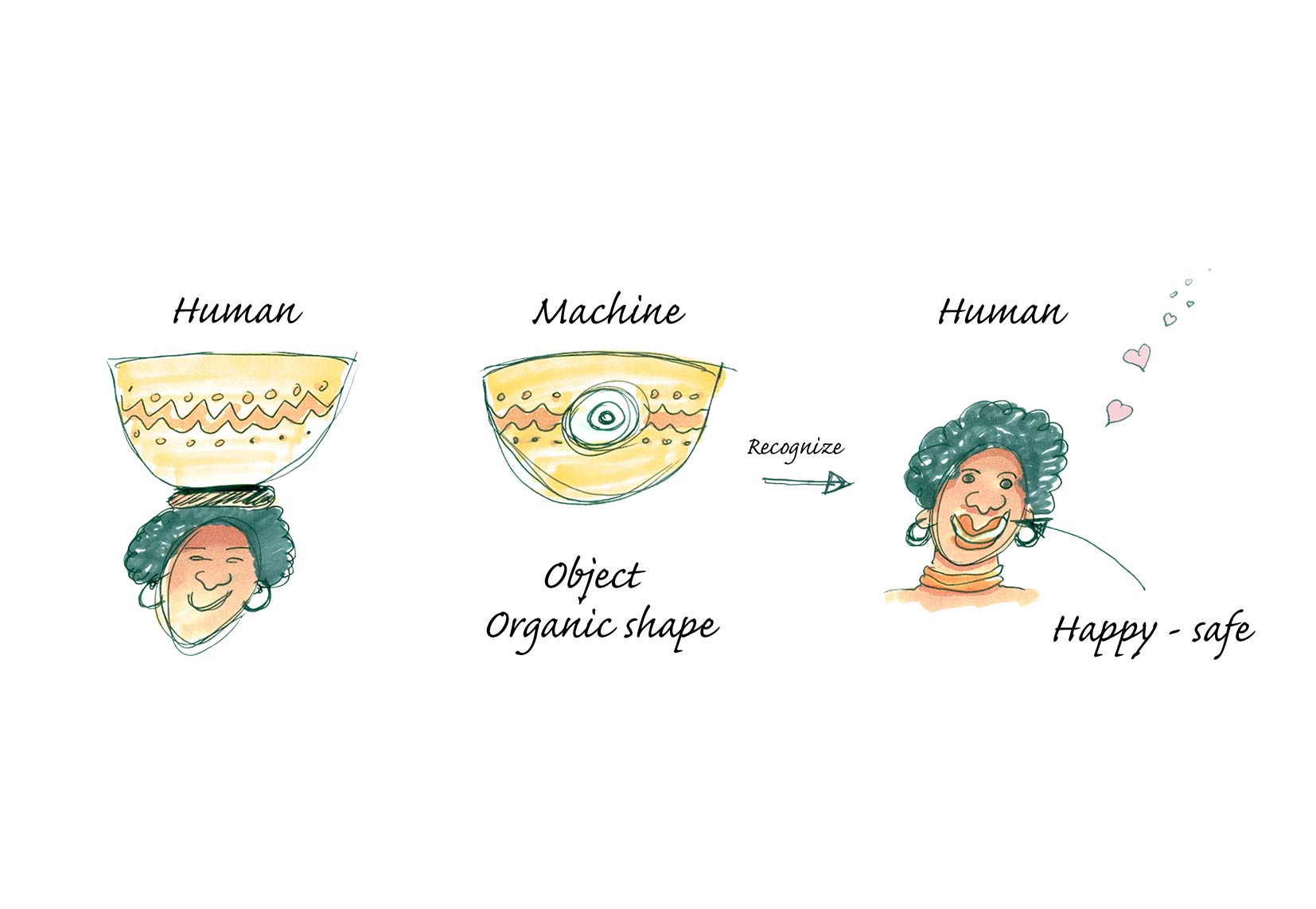

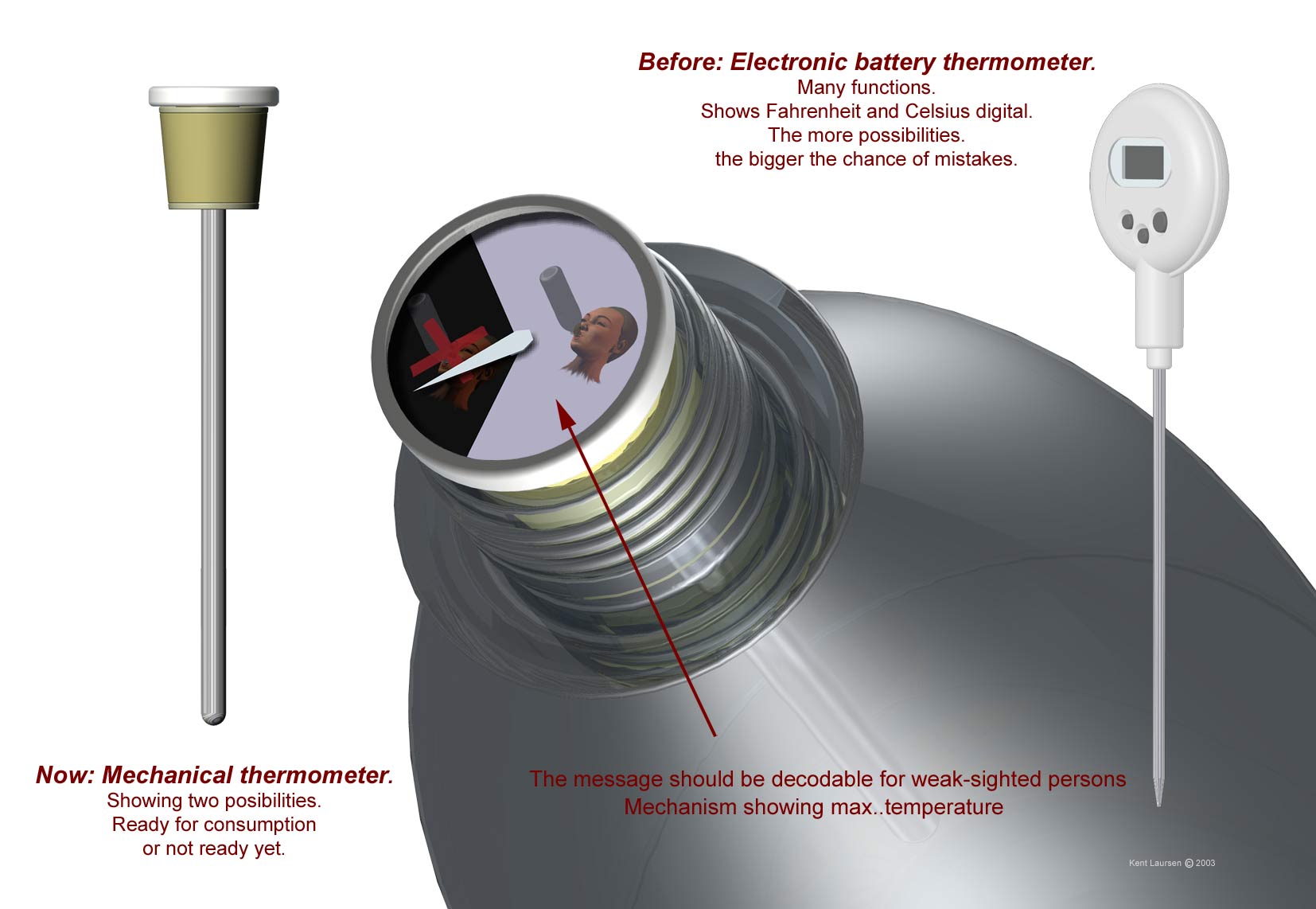

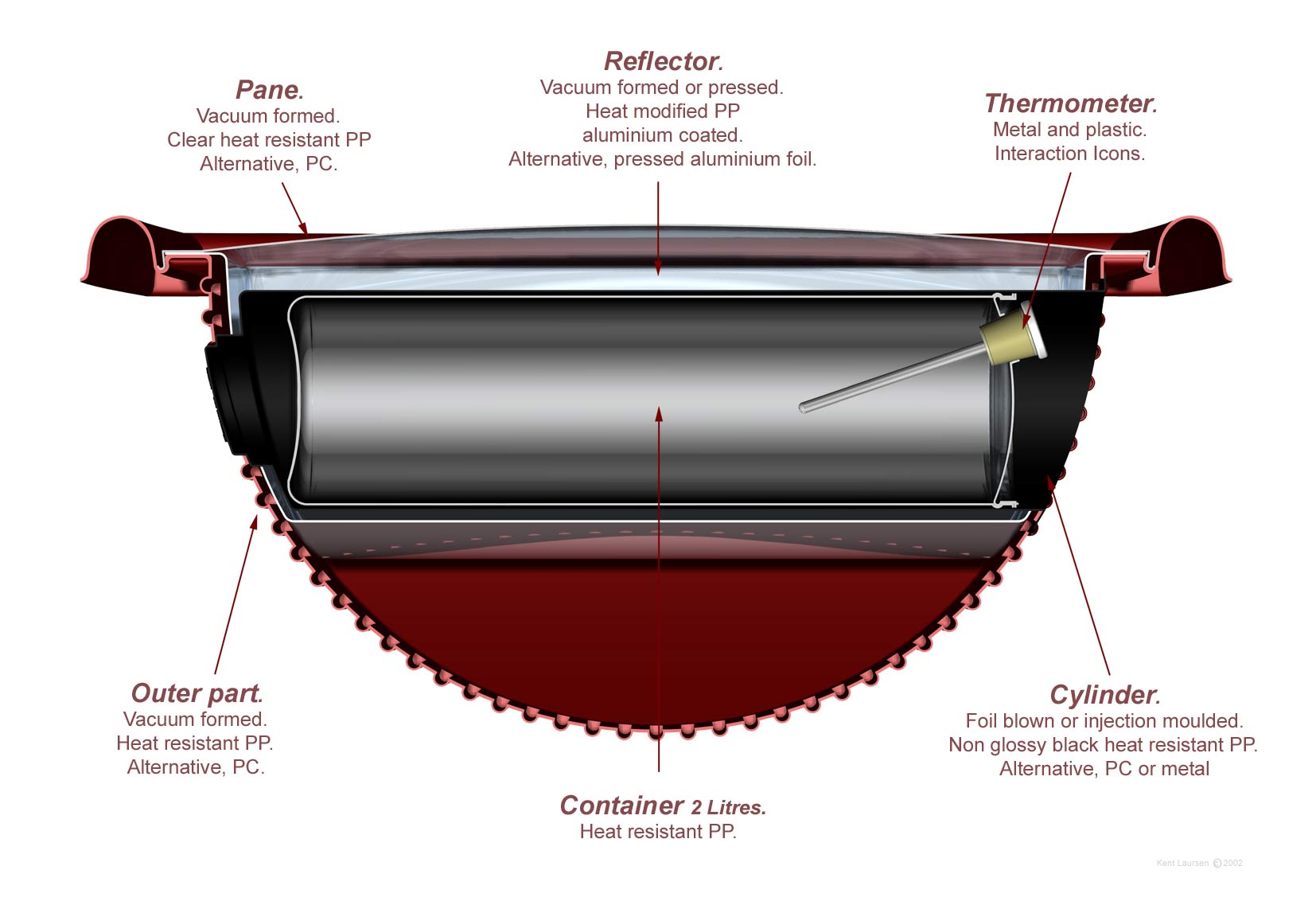

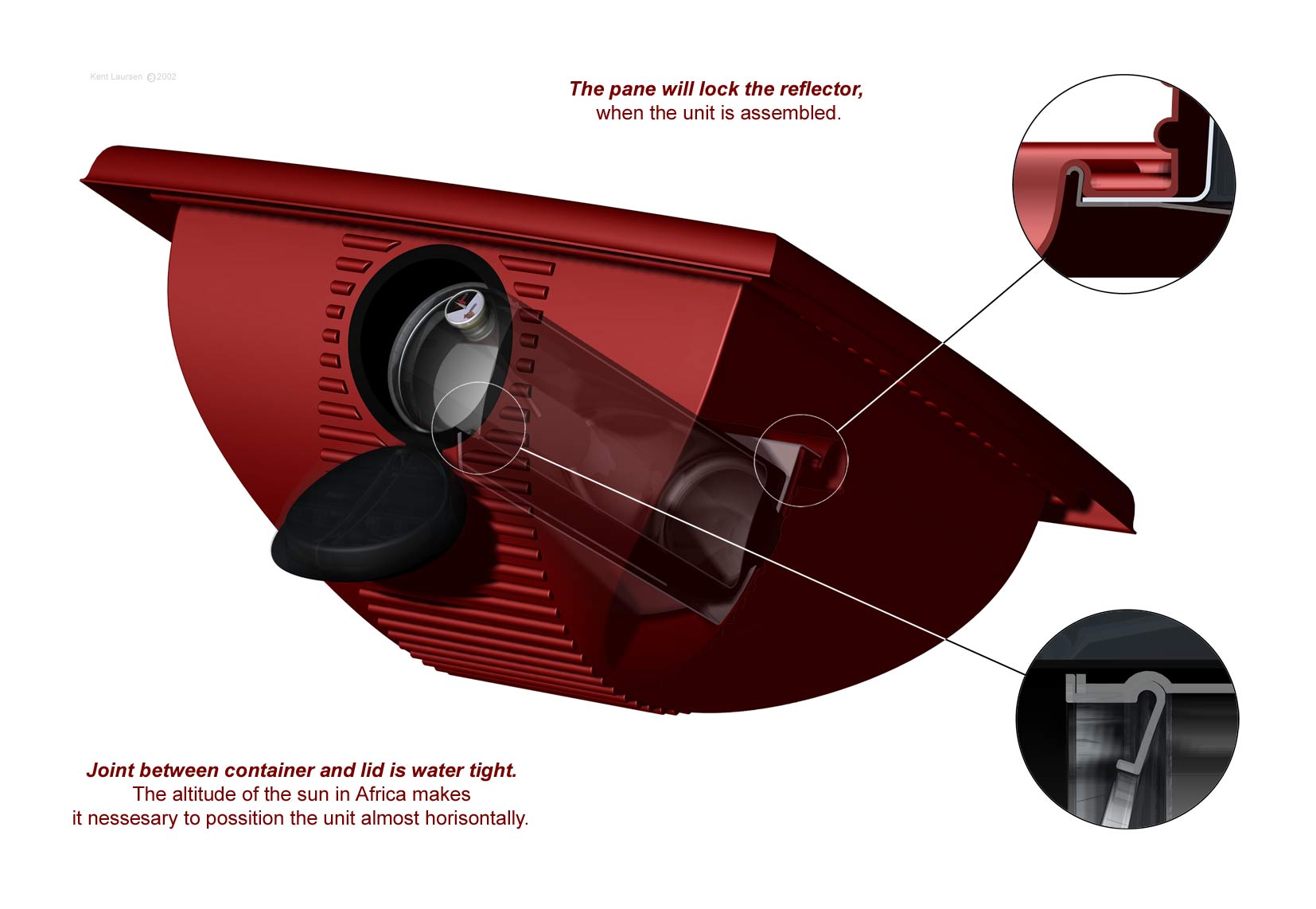

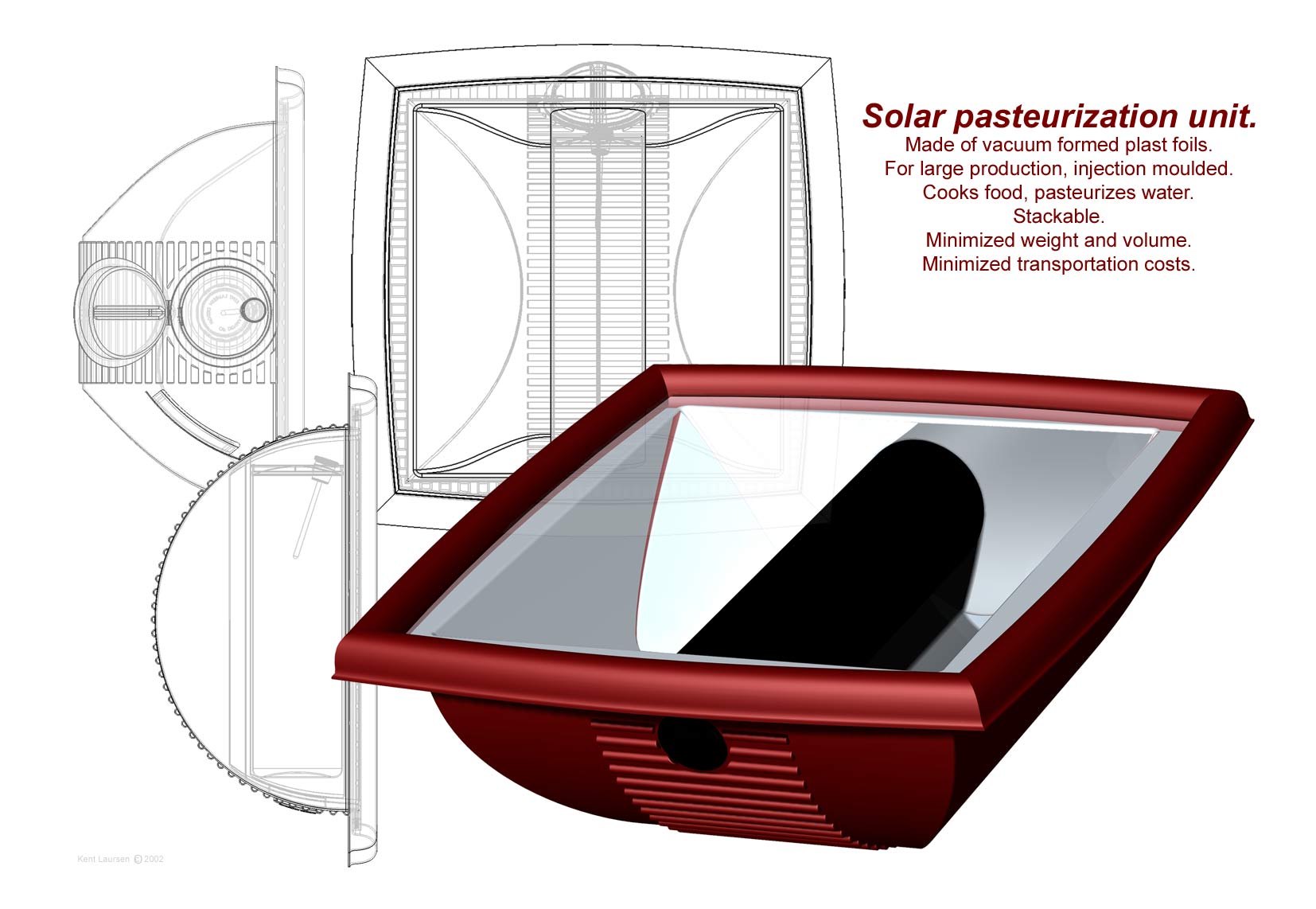

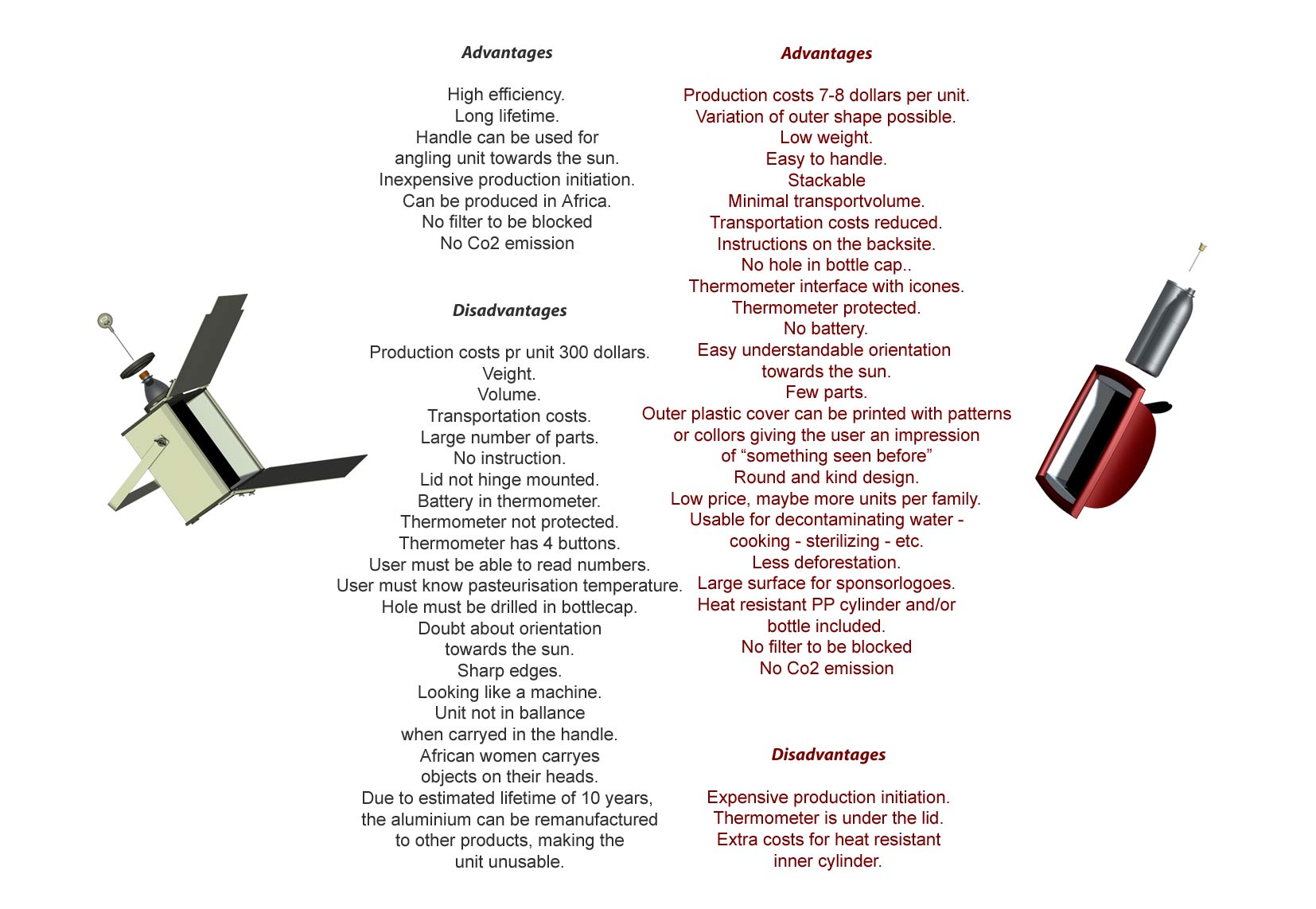

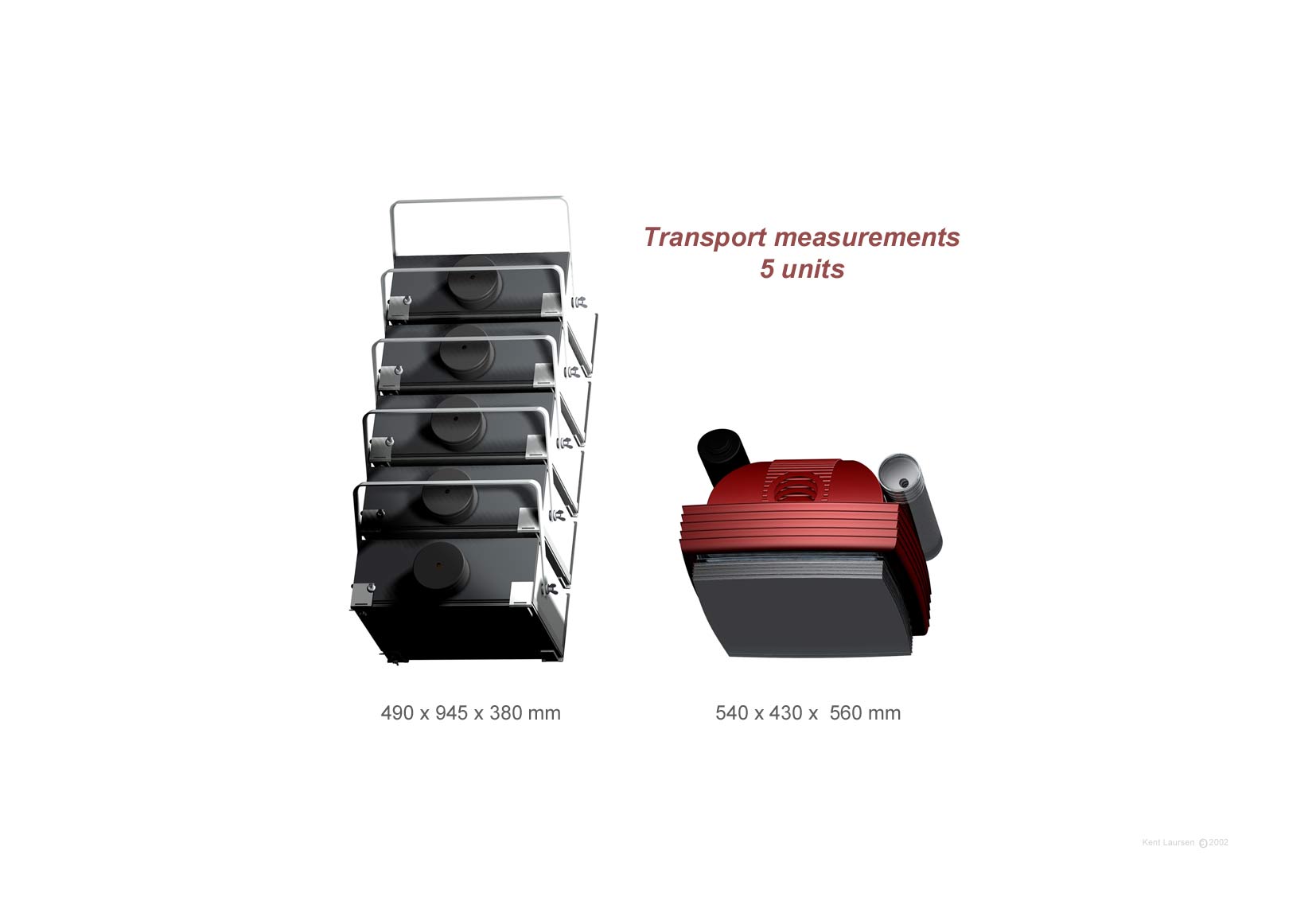

Jeg har i dette projekt arbejdet for Dr. Med. Anders Fjendbo Joergensen, med redesign og produktions optimering af en solvandrenser. Den kan nu laves med emballage teknologi, på de maskiner der fremstiller vacumformet emballage. På daværende tidspunkt, ville det reducere stykprisen fra 2000 kr, til ca. 50 kr. ( 2003 pris ) Du kan herunder se, hvordan jeg illustrerede konceptet, før det blev til et produkt. Produktet er konstrueret i 3D Solid Works, som også er brugt til at lave filer til fremstilling og renderinger der er efterbearbejdede i Photoshop.Redesign of a product

I redesigned a solar pasteurization unit for Anders Fjendbo Jorgensen. Chief Physician. Specialist in Tropical and Infectious Diseases, in 2003. And reduced the costs per unit from 2000 Dkr. to 50 Dkr, using plastic packaging technology. See the outcome here, and read the text, explaining all the work that had to be made by Anders Fjendbo before I became a part of the project.

You can click on the pictures, if you want to read the texts.

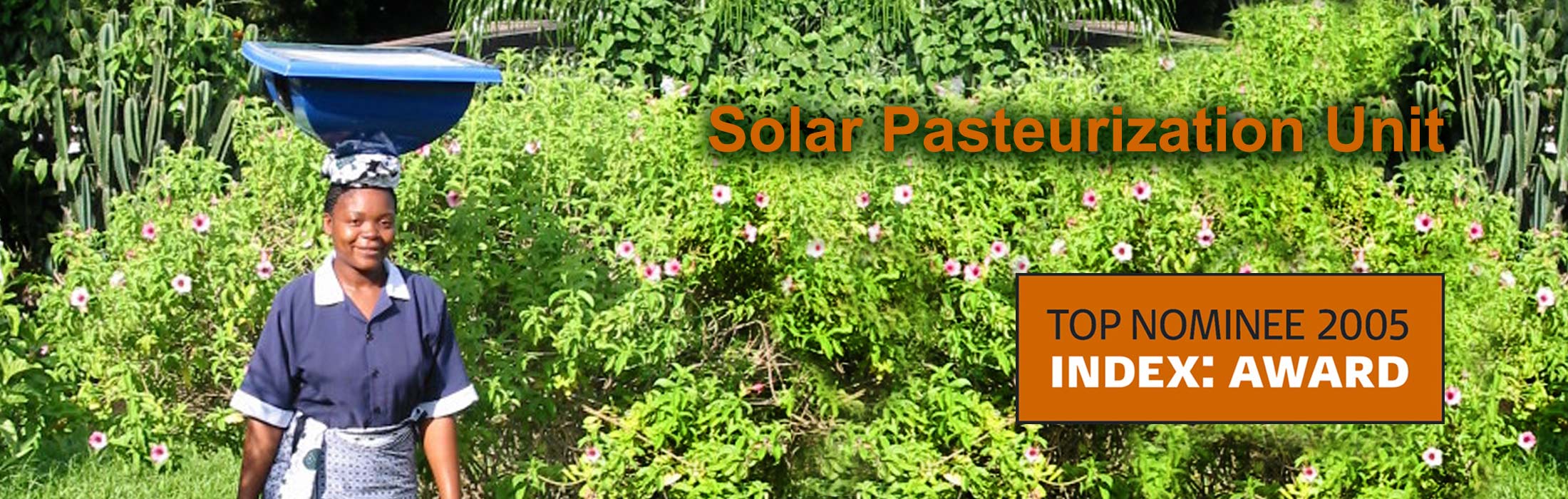

Testing the unit in Tanzania

Here you can see some pictures from the test periode in Tanzania. The tests and the pictures were made by Anders Fjendbo Joergensen. And the models are staff from a Rural Health Clinic. Anders measured, in a scheduled time sequence, the amount of sunlight and the temperature in fluids during pasteurization. Furthermore the temperature in different places in the unit, to be sure the plastic material could stand the heat.

Us - Lifestraw - Itunes and Tesla

We didn’t win the Index Award and the 100 000 euro that year. We were so unfortunate to have Lifestraw as a competitor in the category we were in, And they won. We were proud to be in competition with Apples itunes, and Teslas car and many other big companies. We got a lot of recognition on it and here is a couple of articles, where we were mentioned.